mini-CNC Drill Press

Machine Design Project

Summary :

The Mini-CNC Drill Press is a compact, automated drilling system designed for precision hole drilling in aluminum plates. It features a Cartesian 3-axis motion system (X, Y, Z) and utilizes a microcontroller-based control system for automated operation. The machine is capable of self-probing, auto-zeroing, and executing variable drill sequences, such as single plunge or peck drilling for improved material removal.

This project demonstrates my expertise in mechanical design, automation, and precision machining, integrating CNC motion control, embedded programming, and sensor-based calibration for a functional and reliable drill press

Project Overview

What?

-

Design and fabricate a mini CNC Drill Press capable of drilling 1/4 inch Aluminum plate.

-

Fully autonomous, self probing: auto-zero and self centering.

-

Inderect drive, made with common components.

-

Variable drill sequence: single plunge or pecking modes.

How?

-

Designed in SolidWorks applying GD&T.

-

Used Arduino, fully designed the code program for drill operation to include limit and safety switches, motors, and other peripherals.

-

Designed wiring diagram and determined power requirements.

-

Conducted Critical design review to asses possible failures and limitations using FEA and Mathcad.

Results

-

The mini CNC Drill press was able to accurely drill blind holes and thru holes with an accuracy of ±0.2mm.

Mechanical Model

System Specifications

Specifications

Mechanism Design & Control

Z-Axis SubAssembly:

Z-Axis Linear Rail:

-

Guide rails ensure proper aligngment and eliminate torque from spining spindle.

-

300 mm lead screw: Acme thread 2mm pitch, 2 starts, 4mm lead, allow for linear travel with minmal backlash.

-

Micro Limit Switch- Hinge lever, used for homing axis.

-

NEMA23 & Lead screw Combination: allows for 0.02mm precision per step.

-

VL53L0X Time-of-flight Flight Distance Measurement Sensor, locates part edge (x,y).

Pulley & Motor System:

-

Pullies are directly mounted on shafts (Motor & Quill)

-

Belt Driven system- Timing Belt 5.08mm pitch, 10mm

-

20T Pinion to 40T Gear Pully system: Provides a Gear Ratio of 4:1

-

Spindle/Quill:

-

ER11-C16-150L Collet Chuck: Ø16mm, 150mm, allows for drill bits from 1/16"-1/4"

-

6902-2RS Deep Groove Ball Bearings: Reduce friction and position the spindle within the housing.

-

AXK1730 Thrust Needle Roller Bearings: Minimize clamp friction and support thrust loads on the housing.

-

3D-Printed Spacers: Align the spindle and maintain necessary tension in the housing.

-

C-Clamp Collars: Ensure spindle retention during drilling operations.

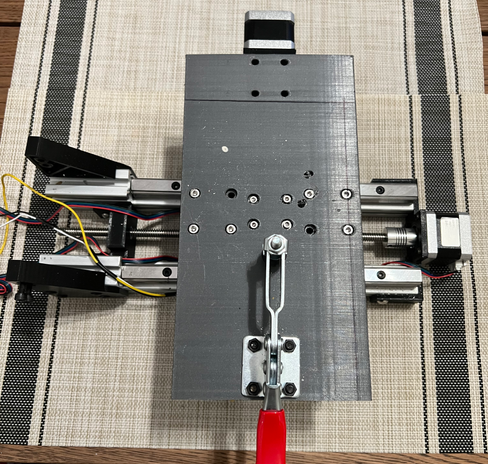

X & Y Axes SubAssembly

1A. Z-Axis Linear Rail:

-

Nema 17 Motor

-

250 mm HGH15CA linear slide rails:

-

Dynamic load rating of 11.38 kN

-

Static load rating of 16.97 kN

-

-

300 mm lead screw

-

PETG 3D printed parts :

-

Base

-

Work bed

-

Y-axis lead screw bracket

-

Motor Bracket

-

Bearing holder

-