6-DOF Robotic Arm

Personal Project

Summary :

The 6-DOF Robotic Arm is a mechanically optimized, fully actuated robotic manipulator designed for precision pick-and-place operations and automation tasks. Built with cycloidal and planetary gear systems, the arm delivers high torque, minimal backlash, and smooth motion control. It integrates closed-loop stepper motors for precise actuation and features a modular end-effector system for tool interchangeability.

Powered by Arduino for low-level control and Raspberry Pi running ROS2 for high-level motion planning, this project explores kinematics, automation, and computer vision for real-time object detection and manipulation.

Project Overview

What?

-

Design a 6 Degree-of-freedom robotic arm or pick and place operations.

-

Integrate computer vision and object detection.

-

Implement ROS2 operating software and peripheral communication thru Rasberry Pi SBC.

How?

-

Designed in Fusion360 and optimized for manufacturability.

-

Cyclodal gear box drives the Z-axis (Joints 1 &2), designed to be 3d printed in any printer.

-

Split-Ring Planetary gearbox drives joint 4 to allow for yaw around the forearm in a compact form.

-

Utilizes Closed-Loop stepper control, with readily available parts.

Results

-

Currently in Design stage of the wrist and gripper.

-

Personal project began as a incentive for my younger cousin interested in engineering, who is currently a freshman at LA city College.

-

This project was a learning experience to adventure into other CAD software, Fusion360.

Mechanism Design & Control

Cycloidal Gearbox

-

Reduction Ratio: 24:1 (One output rotation per 24 input rotations).

-

Design: 25 stationary pins, 24-lobe cycloidal discs, and three-disc configuration for enhanced load distribution.

-

Operation: An eccentric cam drives the discs, engaging stationary pins to convert high-speed, low-torque input into low-speed, high-torque output with minimal backlash.

-

Multi-Disc Benefits:

-

Balanced Load & Durability – Reduces wear and increases lifespan.

-

Smooth Motion – Minimizes vibration, improving precision.

-

Higher Torque Capacity – Handles greater loads efficiently.

-

-

Application: It is used in the shoulder and forearm joints to allow for pitch movement and control.

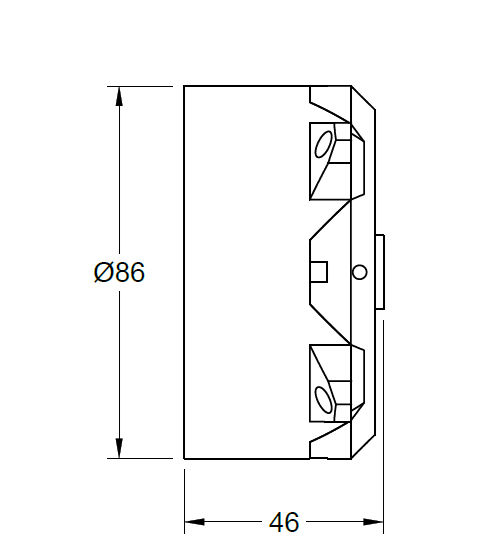

A-Axis SubAssembly

-

It is used in the forearm of the robotic arm and encases a Cycloidal Gearbox and provides an attachment for the roll movement in the arm using a Split-Ring Compound Planetary gearbox

Split-Ring Compound Planetary Gearbox

-

Reduction Ratio: 1:40 (One output rotation per 40 input rotations).

-

Design: Utilizes a split-ring mechanism, where one ring gear is fixed and the other acts as the output, combined with compound planetary gears for enhanced torque transmission.

-

Operation:

-

The sun gear drives compound planet gears, which engage both the fixed and floating ring gears.

-

This multi-stage interaction achieves high reduction in a single compact stage.

-

-

Key Advantages:

-

High Reduction Efficiency – Achieves 40:1 reduction in one stage, reducing the need for additional gear sets.

-

Compact & Lightweight – More space-efficient than traditional multi-stage planetary systems.

-

Minimal Backlash – The floating ring gear improves gear meshing accuracy.

-

High Torque Output – Evenly distributes forces for durability and smooth operation.

-

Base SubAssembly (Yaw)

1A. Z-Axis Linear Rail:

-

Design: The base of the robotic arm is designed with careful consderation of being fully 3D printed with key componets in stress points.

-

3D printed design techniques to avoid overhangs and print with optimal layer adhesion were considered during the deisgn.

-

625-2RS ball bearings placed radially to the load allow for smooth operation

-

Pulley Base system allow for the yaw control of the robotic arm, with a reduction ratio of 13.5:1

-

-

Operation:

-

A NEMA 23 stepper- Base Pulley rotates the robotic arm base to control the yaw.

-

A fan provides necesary cooling in the stepper enclosure that holds the electronics of the robotic arm

-

-

Key advantages:

-

Belt driven system allows for precise control with minimal backlash

-

Higher Torque at output pulley to handle the load of the robotic and pick and place operations

-